PROVECTA PROCESS AUTOMATION is able to offer an exceptional level of experience and expertise in the area of control system benchmarking and tuning. Within PROVECTA we have staff that have been responsible for the benchmarking and tuning of major power stations throughout the USA, Australia, Vietnam, and Sth Korea.

Benchmarking

PROVECTA can offer detailed benchmarking services to assist organisations in assessing the performance of their control systems and identifying associated deficiencies in plant performance. In particular, benchmarking prior to DCS replacement/upgrade can identify processes that would benefit from advanced control strategies, and help quantify those benefits.

Tuning

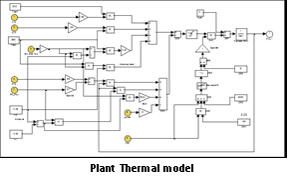

PROVECTA staff utilise specialised PC based tools to provide advanced analysis and optimisation of system performance. Highly controlled procedures are customised for each loop minimise to the impact of tuning on plant operations. Characteristics are calculated over the full operating range to ensure gain and phase margins are maintained under all conditions. System ID tools are applied for high-order systems. Closed loop responses simulated using Simulink® and Protuner® prior to applying settings to the actual plant.

Performance Analysis

Response data is used to construct complex interactive plant models on which advanced control strategies may be applied.

Benefits to Clients – Through the proven experience and expertise of PROVECTA’s staff, your plant can reap the benefits of improved efficiency, extended plant life, increased stability and improved responsiveness – all leading to the ultimate goal of maximum productivity for your plant.

| Should you wish to discuss any aspects of system benchmarking, or tuning, please contact our benchmarking and tuning expert, Mr Don Parker at the following contact details:

Mr Don Parker MEng RPEQ Don.Parker@provecta.com P +1 (224) 420 7982 M +1 (224) 714 7952 |