PROVECTA Process Automation offers two 3-day courses in advanced power plant process dynamics and control loop tuning, which can be delivered on your premises or at a conference venue.

The courses are based on practical knowledge and the application of control theory to power plant processes, aiming to develop a deeper understanding of process dynamics and skills in problem solving and application of test procedures. The format is a combination of interactive presentation, discussion and simulation exercises. Detailed course notes are provided, and extensive use is of made of Simulink® models and tuning calculators which have been developed by PROVECTA for the course. Class size is typically 6 to 12 students.

Simulink® models of boiler and turbine plant components are central to the hands-on tuning exercises that enable each student to see the effects of process characteristics including noise, actuator hysteresis, slew rate limiting, non-linearities, transmitter faults, and interactions with other loops. Plant faults are applied to the models for investigation to develop control system problem-solving skills. Difficult dynamics such as valve non-linearities, inverse drum level response and high-order superheater temperature response are studied, modeled and tuned. MATLAB® and Simulink® are products of The Mathworks.

Module 1

The first module reviews common process responses, controller structures and adjustments including the use of filters, gap action and non-linear gain. Several tuning and calculation methods are compared for relative merits on the power plant environment.

Free tuning calculation software developed by PROVECTA® is provided with the course and several commercial analysis and tuning tools are demonstrated.

The course provides a full set of principles and procedures for testing and adjustment of controller structures including PI, PID, lead-lag PI, Smith Predictor, derivative-model, cascade, multiple drives, adaptive gains and feedforward, with labs using power plant models and realistic controllers.

Module 2

This builds upon Module 1, covering:

- operating characteristics of major plant components such as fans, mills and superheaters to develop a deep understanding of the processes;

- functions, features and performance requirements of major power plant control loops, including different approaches taken in control concepts;

- general structure and tuning of coordinated control systems including Boiler Follow, Turbine Follow and MW control modes;

- performance optimisation and minimisation of control loop interactions;

- functions and limitations of load-frequency control.

For Module 2, dynamic models of the air/gas system, drum/feedwater system, and steam pressure/temperature/flow system enable controllers to be tuned at various loads and tested with load changes and disturbances. Both once-through and drum boiler plant and dynamics can be covered.

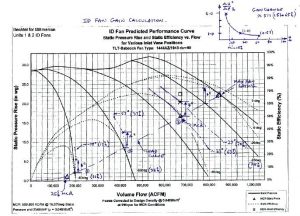

Calculating ID Fan Gain

| Should you wish to discuss any aspect of this training course, please contact our modulating contols expert, Mr Don Parker at the following contact details:

Mr Don Parker MEng RPEQ Don.Parker@provecta.com P +1 (224) 420 7982 M +1 (224) 714 7952 |